Categories

- Heavy Duty > Caterpillar > 3406 > Turbochargers and Accessories

- Heavy Duty > Mercedes > MBE4000 > Turbochargers and Accessories

- Auto / Truck > Honda > Cars / SUVs > Turbochargers and Accessories

- Medium Duty > Cummins > ISC / ISL > Turbochargers and Accessories

- Auto / Truck > Volvo > Cars / SUVs > Turbochargers and Accessories

- Ag / Off-Road > Kubota > Turbochargers and Accessories

- Ag / Off-Road > Caterpillar > Turbochargers and Accessories

- Medium Duty > Isuzu > 4JJ1 > Turbochargers and Accessories

- Heavy Duty > Volvo / Mack > E7 > Turbochargers and Accessories

- Ag / Off-Road > John Deere > 3029 / 3029T > Turbochargers and Accessories

- Heavy Duty > Navistar > MaxxForce A26 > Turbochargers and Accessories

- Ag / Off-Road > John Deere > 5030 / 5030H / 5030T > Turbochargers and Accessories

-

Innovation of Garrett Turbochargers(Post)

The Legacy and Innovation of Garrett Turbochargers When it comes to turbocharging technology, few names carry the legacy and engineering prowess of Garrett. With over six decades of innovation, Garre ...

Benefits of Genuine Turbochargers(Post)Today's top vehicles work at the molecular level to atomize fuel with finely tuned air and fuel pressure maximizing fuel efficiency, while it's component parts are performance matched to control e ...

Turbocharger Troubleshooting(Post)OEM turbos are made to highly specific standards, not only to deliver the power owners demand, but also to keep diesel and gas engines performing at top efficiency year after year. With correct pa ...

Genuine Turbochargers(Post)All Makes Turbochargers OEM turbos are made to highly specific standards, not only to deliver the power owners demand, but also to keep diesel and gas engines performing at top efficiency year after ...

Turbocharger : General Installation Tips(Post)Turbocharger Replacement : A Step-by-Step Guide A failed turbocharger can bring your vehicle’s performance to a grinding halt—literally. Whether you're dealing with loss of power, excessi ...

Garrett 743250-5025S Turbos(Post)Boost Your Performance with the Garrett 743250-5025S TurbochargerWhen it comes to enhancing your vehicle’s performance, the turbocharger is a critical component. For those driving a 2005.5-2007 Ford ...

Holset Actuators(Post)New and Remanufactured Turbocharger Actuators Utilizing genuine replacement actuators for your Holset turbocharger ensures optimal performance and longevity for your engine.Why Choose Genuine? Ho ...

Diesel Particulate Filter Maintenance(Post)Understanding and Maintaining Your Diesel Particulate Filter (DPF)The Diesel Particulate Filter (DPF) is a crucial component in diesel engines, designed to capture and trap soot and ash produced duri ...

About Us(Page)Cardinal Parts: A Legacy of Excellence Welcome to Cardinal Parts, your trusted partner for all things diesel. Our journey began over six decades ago, and our commitment to quality, expertise, a ...

- Product

- Qty in Cart

- Quantity

- Price

- Subtotal

-

On Sale

Borgwarner | New Performance Turbocharger | 14969880005

BorgWarner

Now: $2,456.88Was: $4,527.78Brand: SW - BorgWarner Turbochargers Part Description: Borgwarner | New Performance Turbocharger Our Part Number: 14969880005 Product Notes: -Model S480SXE -1.58...SW14969880005Now: $2,456.88Was: $4,527.78 -

Call for AvailabilityOn Sale

Holset | New Performance Turbocharger | Cummins 5.9L | 4033666H

Holset

Now: $1,909.83Was: $2,064.48Brand: HL - Holset Turbochargers Part Description: Holset | New Performance Turbocharger | Cummins 5.9L Our Part Number: 4033666H Cross Reference Numbers: 4031450,...HL4033666HNow: $1,909.83Was: $2,064.48 -

Call for Availability

Cummins | Remanufactured Turbocharger | Cummins ISB | 3798332RX

Cummins

Only $4,917.71Brand: CU - Cummins Part Description: Cummins | Remanufactured Turbocharger | Cummins ISB Our Part Number: 3798332RX Cross Reference Numbers: 3798332, 3798332NX,...CU3798332RXOnly $4,917.71 -

Holset | New Turbocharger Actuator | 4034114H

Holset

Only $1,252.27Brand: HL - Holset Turbochargers Part Description: Holset | New Turbocharger Actuator Our Part Number: 4034114H Cross Reference Numbers: 4032170, 403217000,...HL4034114HOnly $1,252.27 -

Call for Availability

Holset | Remanufactured Turbocharger | Cummins ISM | 4044006HX

Holset

Only $4,204.73Brand: HL - Holset Turbochargers Part Description: Holset | Remanufactured Turbocharger | Cummins ISM Our Part Number: 4044006HX Cross Reference Numbers: 1700320971,...HL4044006HXOnly $4,204.73 -

Garrett | Turbocharger Mounting Kit | 2007-2010 Sprinter 3.0L - OM642 | 828375-0001

Garrett

Only $17.01Brand: GT - Garrett Turbochargers Part Description: Garrett | Turbocharger Mounting Kit | 2007-2010 Sprinter 3.0L - OM642 Our Part Number: 828375-0001 Cross Reference Numbers:...GT828375-0001Only $17.01 -

On Sale

Garrett | New Turbocharger (Left) | 2011-2012 Ford 3.5L | 855562-5001S

Garrett

Now: $529.50Was: $612.07Brand: GT - Garrett TurbochargersPart Description: Garrett | New Turbocharger - Left Side | 2011-2012 Ford 3.5L | Ecoboost EnginesOur Part Number: 855562-5001SCross Reference Numbers:179204,...GT855562-5001SNow: $529.50Was: $612.07 -

On Sale

Garrett | New Turbocharger (Right) | 2011-2012 Ford 3.5L | 855563-5001S

Garrett

Now: $529.50Was: $612.07Brand: GT - Garrett TurbochargersPart Description: Garrett | New Turbocharger - Right Side | 2011-2012 Ford 3.5L | Ecoboost EnginesOur Part Number: 855563-5001SCross Reference Numbers: 179205,...GT855563-5001SNow: $529.50Was: $612.07 -

Holset | Remanufactured Turbocharger | Volvo D13 / Mack MP8 | 5499741HX

Holset

Only $3,468.06Holset Remanufactured Turbocharger | 5499741HX | Volvo D13 / Mack MP8 | HE451VE OEM Remanufactured Turbocharger The Holset 5499741HX is a remanufactured turbocharger designed...HL5499741HXOnly $3,468.06 -

On Sale

Garrett | Turbocharger Center Housing Rotating Assembly (CHRA) | Detroit Diesel | 408105-5238S

Garrett

Now: $495.01Was: $546.66Brand: GT - Garrett Turbochargers Part Description: Garrett | Turbocharger Center Housing Rotating Assembly (CHRA) | Detroit Diesel Our Part Number: 408105-5238S Product...GT408105-5238SNow: $495.01Was: $546.66 -

Call for Availability

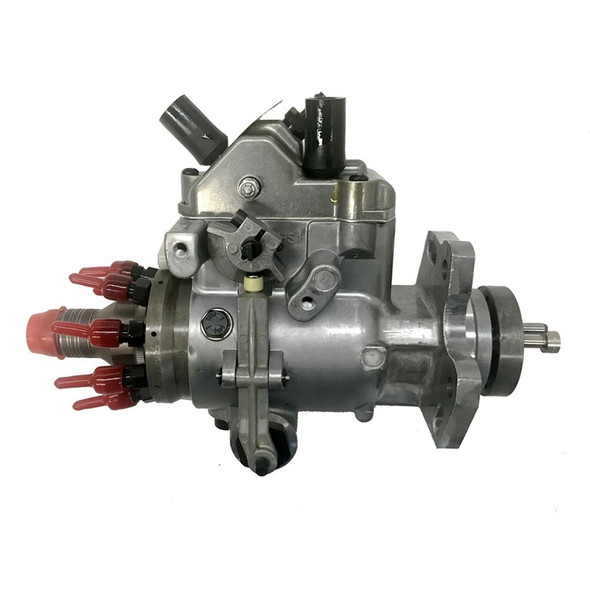

Stanadyne | Fuel Injection Pump | GM 6.5L - Turbocharged | 06282

Stanadyne

Only $3,775.84Brand: SD - Stanadyne Part Description: Stanadyne | Fuel Injection Pump | GM 6.5L - Turbocharged Our Part Number: 06282 Cross Reference Numbers: DB28316282, DB28316364, GEP, 06364...SD06282Only $3,775.84 -

Holset | New Turbocharger | Volvo D13 / Mack MP8 | 5499741H

Holset

Only $4,431.24Brand: HL - Holset Turbochargers Part Description: Holset | New Turbocharger | Volvo D13 / Mack MP8 Our Part Number: 5499741H Cross Reference Numbers: 2841956, 3767704,...HL5499741HOnly $4,431.24

Need Help Finding a Specific Part?

We’re here to make your search easier. At Cardinal Parts, you get access to our vast inventory, trusted supplier network, and remanufactured products to help reduce your replacement costs.

If you're having trouble locating a product, just reach out!

Email our product experts at support@cardinalparts.com

Or call us directly at 888-314-7222